The control system SRM:Control optimizes the speed ratios or the stretch of the tube dynamically when the tube is passing through the mill.

Fig. atrac® saves material and costs and improves tube quality

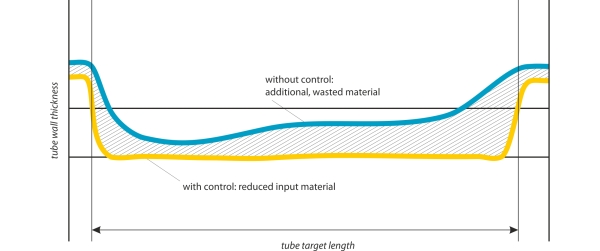

The module SRM:Control.Ends increases the speed ratios and the tension at tube ends. By this function the wall thickening at the tube’s ends is reduced up to 50% or even more and additional tube length with good tolerances is gained.

The modules SRM:Control.Main and SRM:Control.Fine utilise the measuring data of wall thickness and diameter taken over the length of the shell in front of the SRM for adjusting the roll speeds when the tube is running through the mill. This function ensures that the target wall thickness is achieved over the length of the tube as close as possible. Measuring data, which are taken at the tube running out of the SRM, are then utilised for checking the result of the wall control and for a self-learning optimization of the control system. More control modules, like SRM:Control.Length (constant good-tube-length), SRM:Control.MotorLoads (avoiding peak overloads), are available if requested.

A special and unique function of atrac® is SRM:Control.StandLoads, a function which helps to prevent overloads on rolling stands and thus avoiding damages on the stands, breakage of couplings and production interruptions.